Applications of the Macaroni Production Line

The Automatic Macaroni Production Line is designed for production of Macaroni, Italian Pasta. Different molds can produce shells, spirals, round tubes, diagonally cut round tubes, hollow shapes and other novel and unique shapes. It can be used for steaming or deep-frying, and is suitable for daily meals and restaurants.

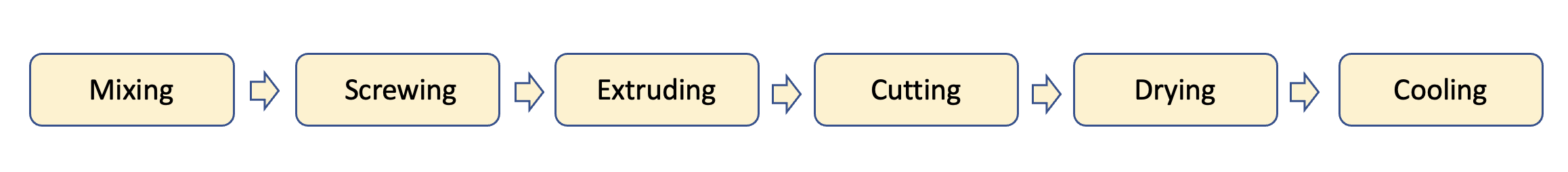

Macaroni Production Line Process Flow Chart

1. Mixer:

Mix the raw material powder with water and stir it evenly. It is made of stainless steel and does not leak during the mixing process. The effect of high-speed mixer is better than low-speed mixer.

2. Conveyor:

Convey the mixed material in the stainless steel drum to the extruder feeder. No dust, no pollution, no leakage during the conveying process.

3. Extruder:

Extrusion of the raw materials is a very critical step. The continuous vacuum extrusion technology is adopted. The frequency converter controls the speed of the main motor, cutter motor and feeding motor.

4. Cutting machine:

Mainly for cutting the surface, and the cutting speed can be adjusted.

5. Dryer:

It is used for baking and drying products, and the drying method can choose the heating method of gas, steam, and diesel. The running speed of the mesh belt can be controlled by a frequency converter, or electric heating, with an automatic temperature control system.

To cool the dried food, lower the temperature of the macaroni, and make the product easy to pack.

Automatically packing the finished product, weighting, printing the date and sealing.

Advantage of the Automatic Macaroni Production Line

1.Fully automatic, high efficiency and stable performance.

2.Diversified product specifications to meet the needs of different customers.

3.Scientific and reasonable structural design, all spare parts and accessories are domestic or international brand-name products.

+86 18217202325

+86 18217202325  info@jdqproducts.com

info@jdqproducts.com