Applications of the Biscuit Production Line

This automatic biscuits line is designed for production of Tough biscuits and Shortbread biscuits. We provide basic recipe for making kinds flavor biscuits, as well as biscuits molds in different shapes to meet various marketing demands.

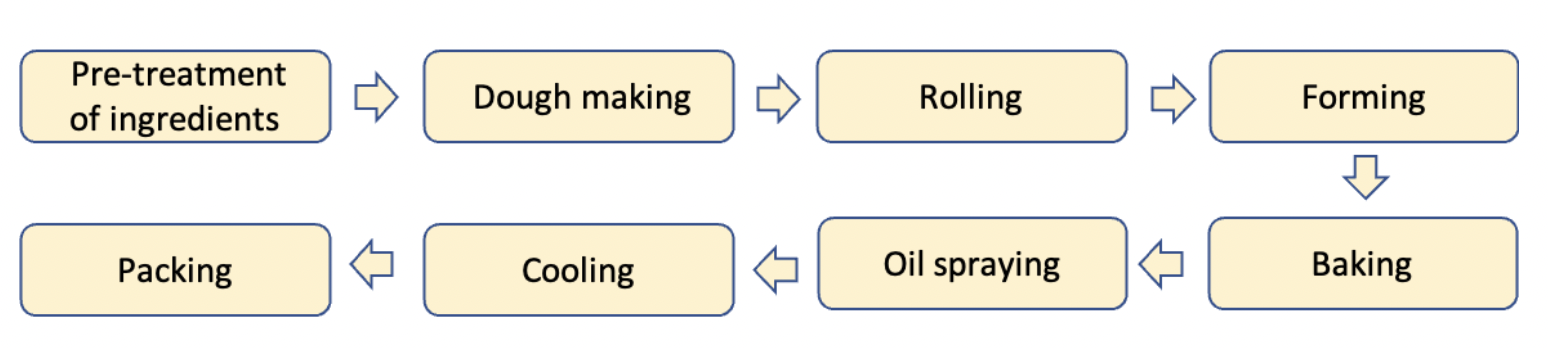

Biscuit Production Line Process Flow Chart

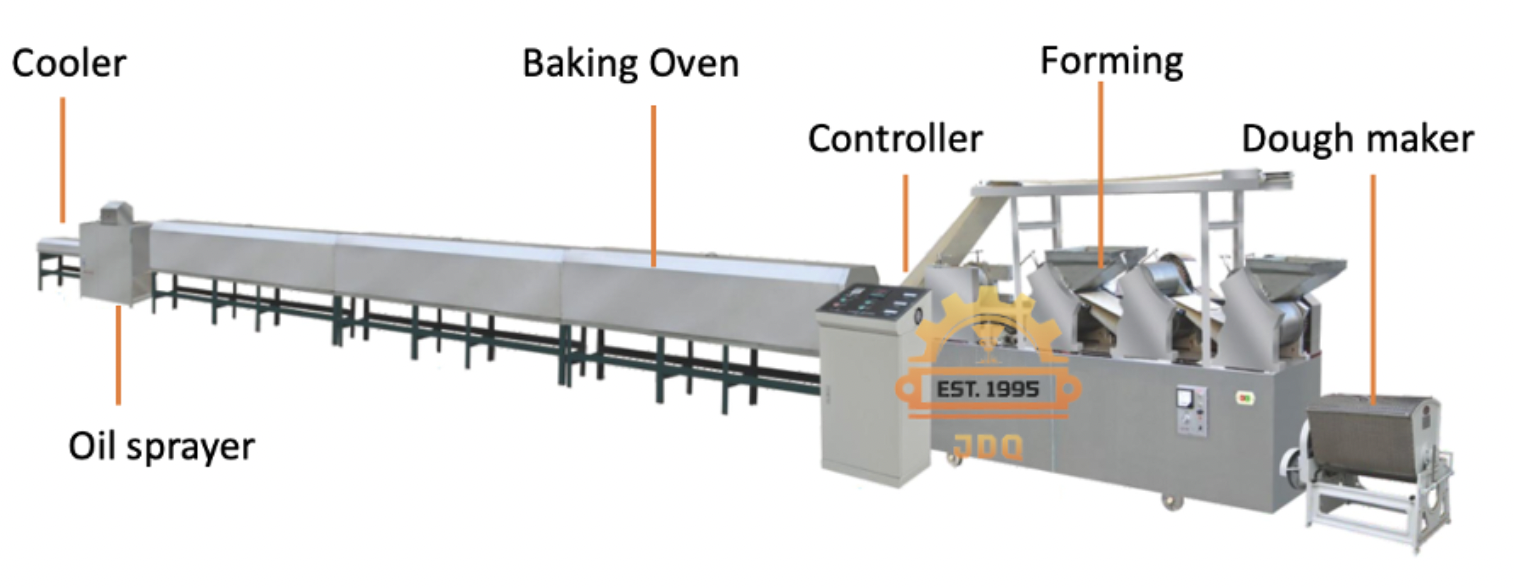

1. Dough Mixer

The mixing machine is for stirring flour and water into dough. It can be used as a stand-alone machine or in combination with other equipment.The inner drum is stainless steel to ensure food safety. It can mixing 20 kg every time.

2. Forming machine

Roll printing, roll cutting type dual-use forming machine with 3 channels of continuous surface pressing of tie rollers, automatic forming, automatic waste recovery, frequency conversion speed control.

3.Electric baking oven

The electric baking oven is energy saving tunnel oven, which adopts far infrared electric heating. The baking temperature is controlled automatically and the height is adjustable. It consists 5 sections with total length 10m.

4.Oil spraying machine

This machine is used to spray oil on the surface of the baked biscuits, this step can make the biscuits looked bright and tasted delicious. Automatic oil spraying, automatic constant temperature, automatic filtering, the amount of oil spraying can be adjusted and controlled.

5.Conveyor

Cooling for the biscuits after oil spraying, speed adjustable, natural cooling on the net belt.

Advantage of the Automatic Biscuit Production Line

1.One-time roll forming, high forming rate and good forming quality.

2.The drying box way is assembled in sections, which is easy to clean, install and transport.

3.Perfect technology, compact structure, stable and reliable performance.

4.Less investment and fast results, suitable for small, medium-size and inpidual enterprises.

+86 18217202325

+86 18217202325  info@jdqproducts.com

info@jdqproducts.com